Freight volume increased throughout 2011, but the excitement of new business was accompanied by a constant drumbeat of concern about capacity shortages. That’s because the industry lost as many as 325,000 trucks, representing 18% of available capacity, from 2007 through 2010,* according to industry analyst Donald Broughton of Avondale Partners. Although fewer carriers and trucks left the market in 2011 than in any recent year, according to Broughton, higher truck prices, lower availability of credit and other factors slowed the rate of replacement.

One result of the capacity shortfall was an increase in freight rates during 2011, especially during periods of high demand. Rate increases did not, however, lead to higher profit margins for most trucking companies. The Stephens TL Index was down 24% for the year, and its LTL Index slid 21%, making 2011 “the worst year so far this century” in terms of stock performance for publicly traded carriers, according to the investment analyst’s January 11 Industry Note. Stephens blamed barriers to asset utilization, including regulations, an anemic economy and driver shortages. Small carriers were hit hard, too, as costs continued to outpace revenue growth for 97% of the for-hire carriers who have 20 trucks or fewer.

Despite high unemployment in 2011, carriers were not able to add enough drivers to meet demand. For-hire trucking added just over 40,000 jobs in 2011, a 3.2% increase, according to estimates by the Bureau of Labor Statistics, but the total number of jobs has yet to exceed 1.3 million, which is 10.8% lower than peak employment of January 2007. Regulations such as the CSA safety program did not have as much impact as anticipated, but the program scrutinizes drivers more closely and holds carriers responsible for their employees’ performance behind the wheel. Mandatory Electronic Onboard Recorders (EOBRs) are also blamed for discouraging drivers, who might be less willing to take long haul assignments. Driver wages are relatively stagnant, so the recession isn’t entirely over for them.

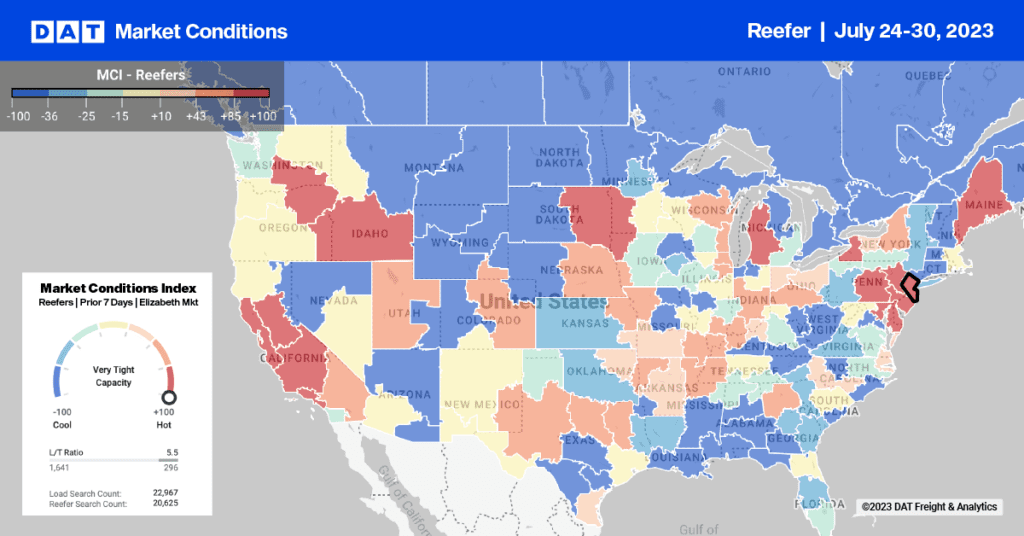

Capacity constraints led to some new tactics in supply chain management at shipping companies. Shippers turned to their contract carriers first, but when those companies couldn’t provide enough trucks, 36% more freight was funneled to intermediaries and to the spot market. For-hire truck tonnage increased by 5.7% for the year, according to preliminary data from the ATA, so the spot market grew faster than the industry overall. Surveys indicate that for-hire carriers are entering into shipper contracts for shorter terms, too. Some carriers even reserve capacity for the spot market, especially during peak seasons, to take advantage of higher rates.

Illustrations by Eric Savage of Savage Creative

The Road Ahead: More Trucks in 2012, but Maybe Not Enough

The outlook for capacity in 2012 is mixed. New Hours of Service rules were not as bad as anticipated, and CSA did not have as big an impact as expected, according to a research report quoted in Heavy Duty Trucking. Fuel prices are declining, at least for now, relieving some cost pressure on carriers.

In one sign of an optimistic outlook, carriers are buying new trucks again. Class 8 truck sales rose 46% in December, compared to weak November sales, bringing the expected total to 312,000 units for the year. That represents 13% or one eighth of the 2.4 million Class 8 trucks that were on the road in 2010, according to the American Trucking Associations, but a large portion of the new vehicles are likely to be replacing outdated trucks rather than adding to fleet size.

Commercial trailers also enjoyed robust year-end sales, with 29,000 units in November setting a record for the highest single-month volume since March 2006. These surges could indicate optimism on the part of carriers, who were reluctant to increase fleet sizes throughout 2011.

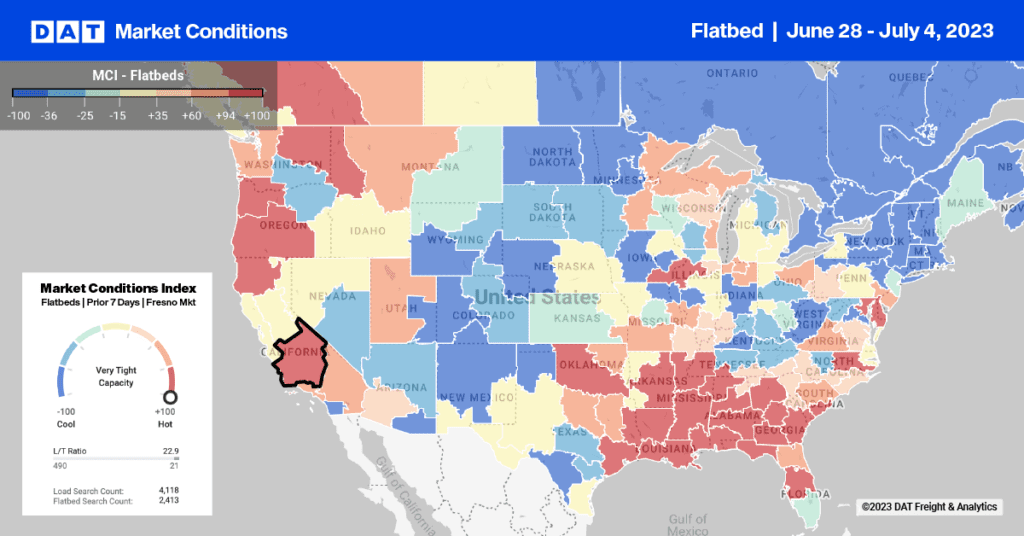

At the same time, any economic growth could lead to increased demand for freight transportation. An upswing in construction, in particular, could squeeze flatbed capacity, which was already tight throughout much of 2011. Expect shippers and intermediaries to look for creative solutions as the year progresses, shifting some freight to rail intermodal for the longest hauls and delivering imported goods by sea directly to the Gulf and Atlantic Coasts, closer to the centers of consumption.