If there’s one thing logistics has taught us, it’s that you don’t need more data – you just need the right signals at the right time.

Shippers, brokers, and carriers all live inside the same reality: markets shift fast, tender behavior changes overnight, dwell time spikes unexpectedly, and capacity can swing from abundant to tight or vice-versa in weeks (although we have not seen the market move in the last few months at the time of this writing). The challenge isn’t access to data. It’s knowing which signals actually matter and watching them consistently enough to act before the disruption hits.

After working with freight data every day, from facility dwell to broker pain to market conditions, I have realized that there are five signals every freight leader should monitor weekly. These are the ones that reduce surprise, improve planning, and give you an operational advantage.

Let’s break them down.

Tender behavior: Are your customers (or carriers) telling you something?

Tender data is one of the earliest and clearest signals of market movement.

For shippers: rising rejections often indicate future rate pressure. For brokers, sudden changes in tender volume show you where customers might be shifting freight. For carriers, declining tenders in certain lanes signal softening demand.

The pattern matters more than the number. If tender rejections move up for 2-3 weeks straight, pay attention and it could be that the market is warming.

Dwell time: The quiet margin killer

Dwell time doesn’t just delay freight. It creates a ripple effect across your entire network including missed appointments, lost driver hours, service failures, higher detention exposure, and weaker routing guides.

Most organizations underestimate how quickly dwell can deteriorate. If a facility’s average dwell jumps by 25-30% week-over-week, you will feel it in:

- on-time performance

- load acceptance

- transportation cost

- carrier experience (and churn)

This is one of the most powerful operational signals you can track and one of the most ignored.

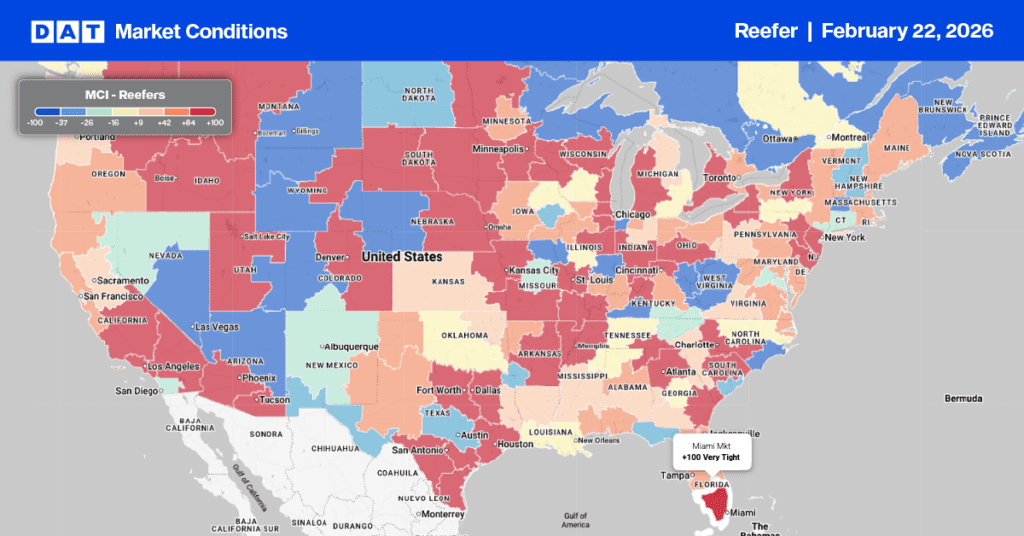

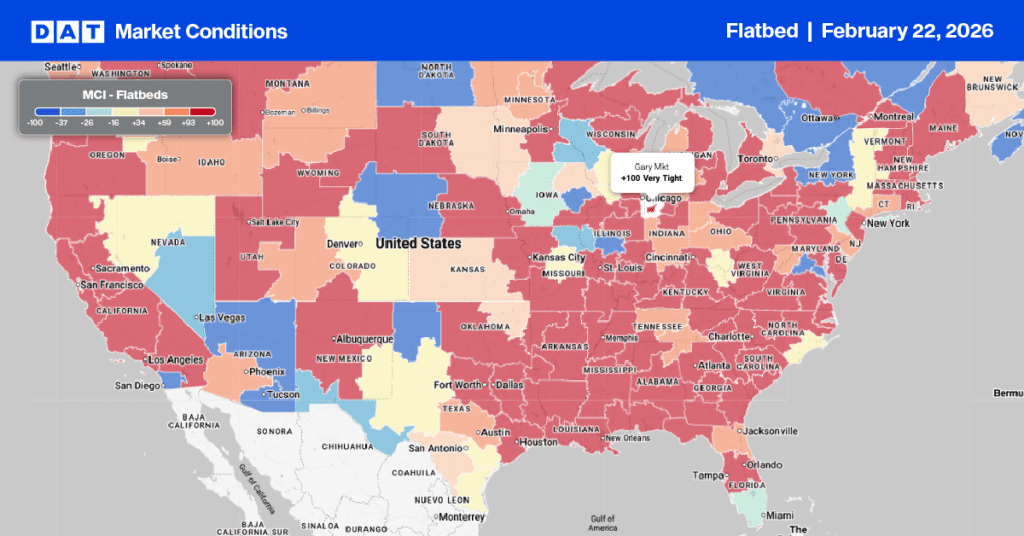

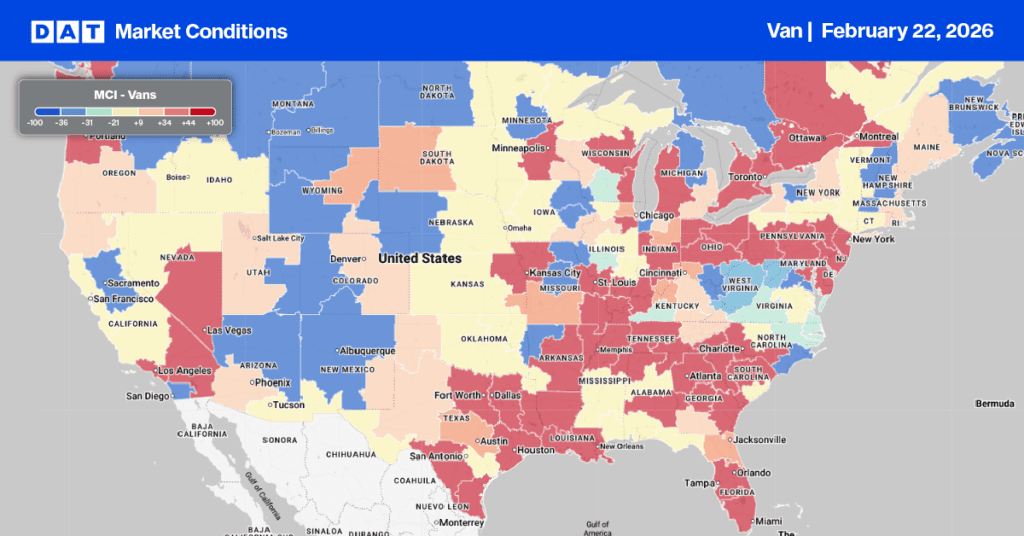

Market conditions (demand vs. capacity)

Every week, look at how demand and capacity are trending in the lanes you care about. The changing patterns of demand and capacity gives a fair picture of tightening or loosening conditions of the freight market.

A few questions to ask yourself:

- Is capacity tightening faster than normal seasonality?

- Are rates drifting upward in pockets despite a soft national market?

- Is search/post behavior changing for that region?

- How does market conditions look in larger markets vs smaller markets?

Market tightness is the context behind every rate you see. Without it, decisions default to guesswork.

Service and routing guide performance

How is your freight behaving inside your own network?

High-performing organizations look at:

- primary acceptance rates

- waterfall depth

- tender lead time

- on-time pickup/delivery

- carrier performance trends

- lane-level exceptions

These internal signals tell you whether your processes can withstand the next disruption. Weak routing guides are often the first indicator that a market shift is about to hurt you.

Cost signals: Rates, accessorials, and variability

You don’t need to track every rate movement but you do need to understand:

- week-over-week rate shifts

- lane-level volatility

- accessorial exposure (detention, truck order not used, layover)

- variance between spot and contract. Is there a lagging/leading between spot and contract rates ?

A rate by itself is not a decision. A rate paired with context is.

If the market is tightening and your routing guide is slipping, a rising rate is a signal to act and not a surprise to react to three weeks later.

Bringing it all together

The real power of these signals comes when you look at them together.

Here’s a simple truth: When two or more signals move at the same time, a market change is already underway.

For example:

- Increasing market tightness + rejections rising could be an indication of rate pressure incoming

- Increasing dwell time + carrier falloff could indicate towards operational friction building

- Routing guide slipping + spot variance rising could imply budget risk expanding

You don’t need perfect dashboards to be data-driven. You just need discipline that involves a weekly habit of looking at the signals that matter.

Why this matters right now

Freight leaders who rely on lagging indicators will always be few steps behind. Those who build a weekly signal-based routine, even a simple one will operate with more confidence, more predictability, and far fewer surprises.

Whether you’re a shipper, a broker, or a carrier, these signals help you to:

- respond faster

- plan smarter

- reduce avoidable costs

- strengthen relationships

- build a more resilient network

Data is not just about insight, it’s about timing. And the teams that move quicker win.

If you’re looking for a place to start or want to strengthen your decision-making with actionable signals, DAT Freight & Analytics has some of the best datasets in the industry to help you build this weekly discipline.