The Operation Airbrake program is this week courtesy of the Commercial Vehicle Safety Alliance (CVSA). While it’s scheduled to run from Aug. 21 to 27, there will be a second one-day event, which may be held any time this year.

Properly functioning brake systems are crucial to safe commercial motor vehicle operation, so carriers and drivers shouldn’t need to do anything to prepare. Why? Because heavy vehicle brakes should be in top working order all the time. Brake-related violations comprise most of all out-of-service violations cited during roadside inspections during inspection weeks. Of the 35,764 commercial motor vehicles inspected in 2021, 12% were placed out of service due to critical brake-related violations.

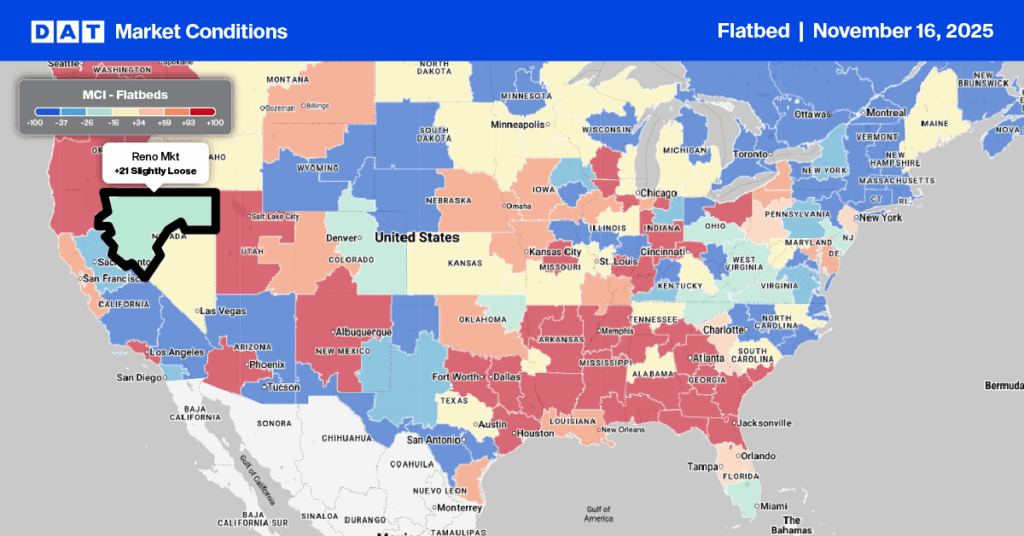

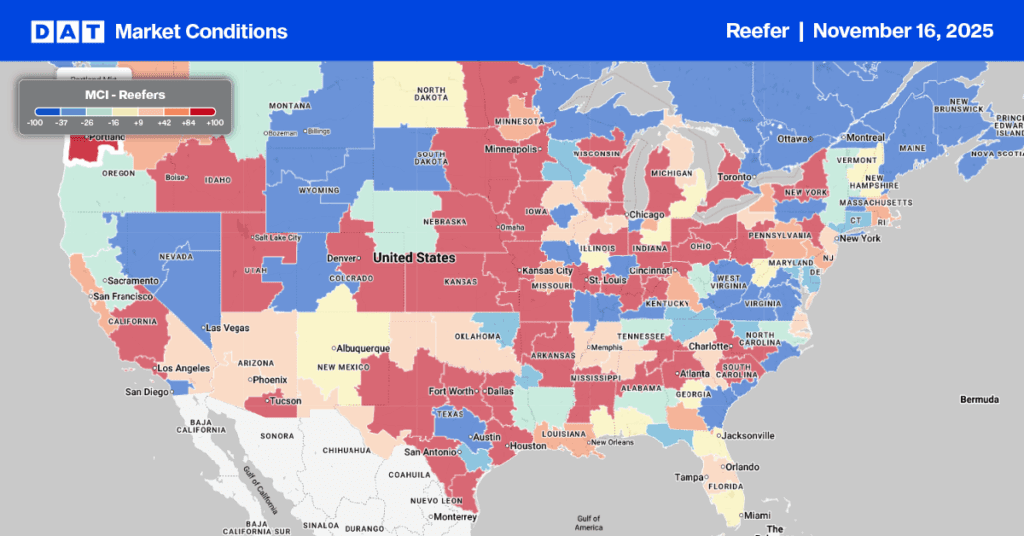

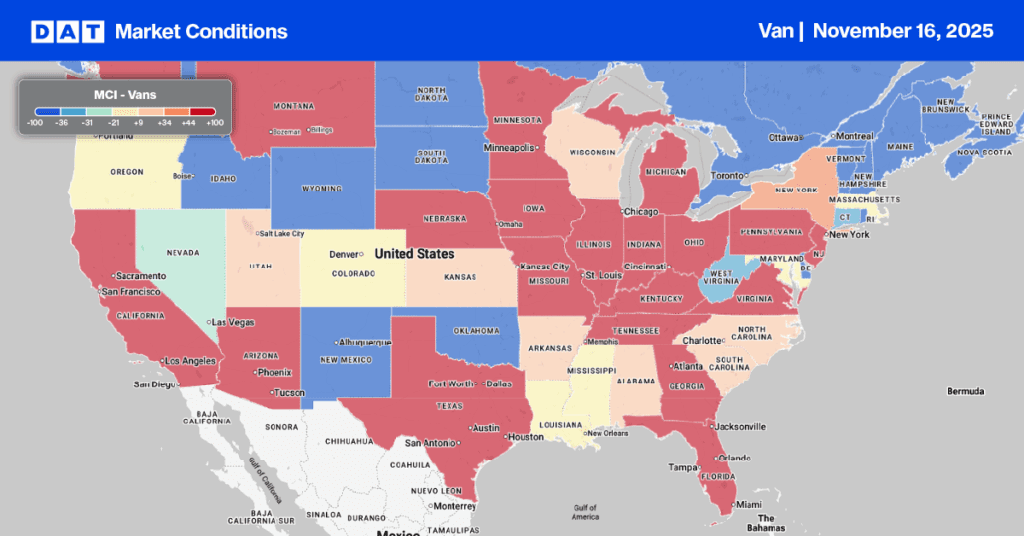

Get the clearest, most accurate view of the truckload marketplace with data from DAT iQ.

Tune into DAT iQ Live, live on YouTube or LinkedIn, 10am ET every Tuesday.

According to data from the U.S. Federal Motor Carrier Safety Administration (FMCSA), brake-related violations accounted for eight out of the top 20 vehicle violations. And brake system and brake adjustment violations accounted for more out-of-service vehicle conditions than any other vehicle violation during CVSA’s three-day International Roadcheck inspection and enforcement initiative last year.

The focus this year is on chafing.

In addition to reporting comprehensive inspections and brake-related out-of-service violations, inspectors will capture and provide data on brake hose/tubing chafing violations – the focus area for this year’s Brake Safety Week. For those that are not sure where inspectors will focus their attention, here are the top 10 areas they’ll be inspecting:

- Inspecting brake hoses and tubing as part of your pre-trip and post-trip inspection

- Reporting any issues in your driver vehicle inspection reports (DVIR).

- Look for brake hoses that are in contact with steering, suspension, brake or other components, or the tires or frame.

- Listening for air leaks, identifying the leak’s location, and making the necessary repairs before leaving.

- Inspect brake hoses to ensure they’re not kinked or improperly repaired.

- Ensure air lines are not hanging down and touching the tractor deck or frame.

- Checking for abrasion wear on hoses or tubing making contact with other components.

- If a hose or tubing is chafing and has caused a reduction in diameter or, on thermoplastic hoses, the secondary white color is visible, a violation exists.

- If a hose is worn or the reinforcement ply is cut or abraded, this is an out-of-service condition and should be replaced immediately.

- Make sure all repairs are consistent with the manufacturer’s requirements and guidelines.

While recent inspection weeks have focused on maintaining brake components and brake adjustment, more recent campaigns have also emphasized the importance of proper brake hose and tubing installation, inspection, and maintenance. Brake hose chafing is one of the more common vehicle violations and one that can affect a motor carrier’s safety rating. The CVSA has created a 2022 Brake Safety Week flyer, which may be downloaded, printed, and provided to drivers and motor carriers leading up to and during Brake Safety Week.